SERVICES

Test & Tag

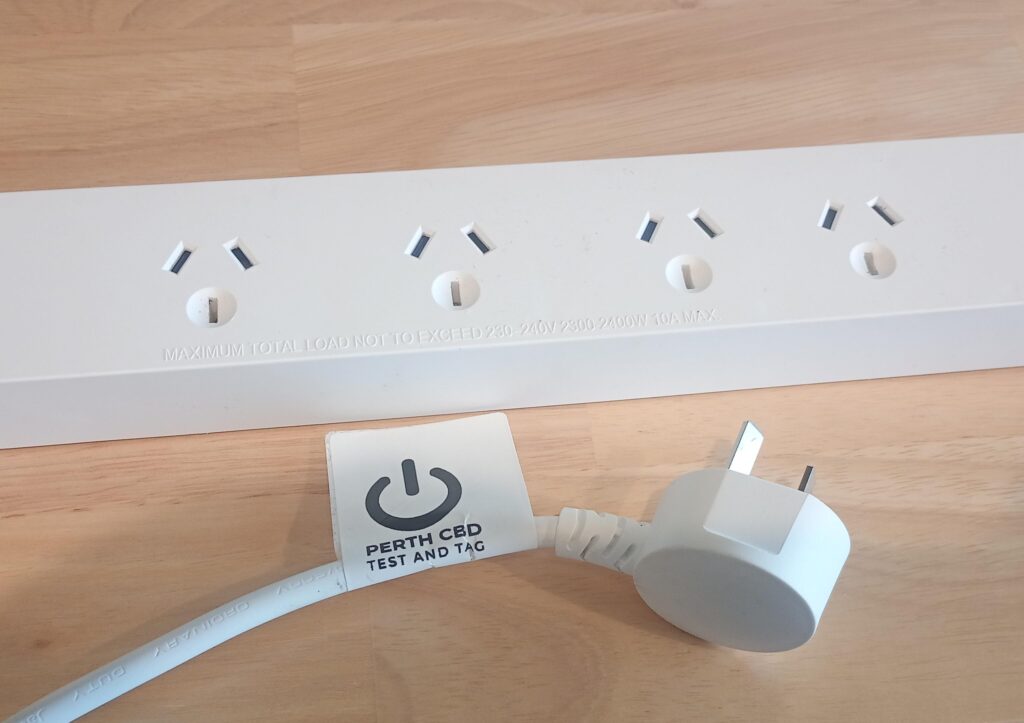

Test and Tagging, also known as portable appliance testing (PAT), is the essential process for guaranteeing the safety of any electrical device that’s designed to be moved. This covers everything from your power boards, extension cords, computer monitors, printers and RCD’s.

The core purpose of Test and Tagging is to shield people in the workplace from electrical dangers like shocks and fires. Regular checks are fundamental for preventing accidents and fostering a secure, reliable environment for everyone. As an added benefit, this proactive maintenance can also help to extend the operational life of your valuable equipment.

Crucially, all Test and Tagging conducted in Australia and New Zealand rigorously adheres to the AS/NZS 3760:2022 Australian Standards. This commitment ensures consistent, top-tier safety practices you can always trust.

What we Test

Electrical equipment are categorized into main 3 classes:

- Leads Class: These include extension leads, power boards and EPOD’s

- Class 1: These are earthed appliances, such as kettles, toasters, microwaves and irons

- Class 2: These are double-insulated appliances, typically identified by a double square symbol Examples include electric drills, hair dryers and lamps

Extension Cords

Power Boards

Monitors

Kitchen Appliances

Power Tools

What our Testing Involves

Our comprehensive Test & Tagging service involves three critical phases:

- Thorough Visual Scan: We begin by meticulously inspecting every inch of the appliance. Our experts look for any obvious signs of wear, damage, or potential hazards, such as bent or cracked plugs, frayed cables, or cuts in the cord, which are often the first indicators of a problem.

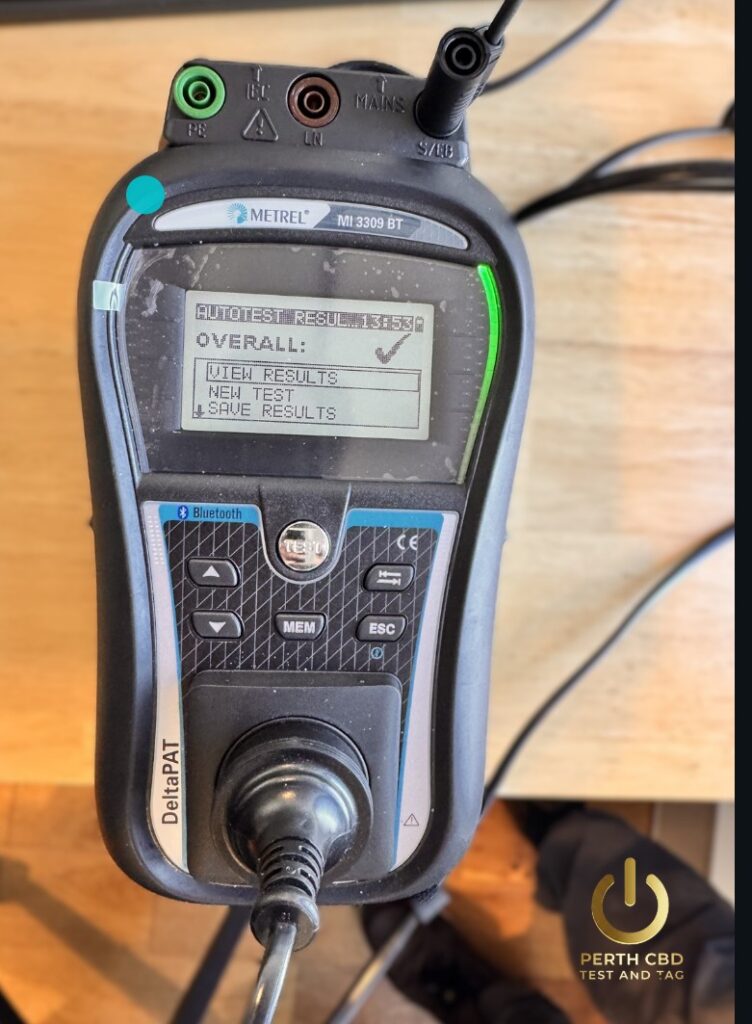

- Precision Electrical Assessment: Following the visual check, we connect the appliance to a state-of-the-art Portable Appliance Tester (PAT Tester). This sophisticated device performs essential electrical integrity checks, including verifying earth continuity, confirming correct lead polarity, and measuring insulation resistance, all vital for preventing shocks and short circuits.

- Transparent Reporting & Tagging: Once the testing is complete, each appliance receives a clear, compliant safety tag indicating its status. All inspection and test results are then meticulously recorded within our digital reporting software, providing you with a transparent, accessible history of whether each item successfully passed or failed our rigorous assessment